Ceramic set of nanocosmetis for car

Ceramic set of nanocosmetis for car

Have Pikatec applied by a professional in our application centres.

Have Pikatec applied by a professional in our application centres.The closest one is from you at the address:

Unique nanotechnological cosmetics that create an invisible transparent layer of nanoparticles (a millionth of a metre) on the car’s lacquer or glass have a width of only several nanometres. The nanoparticles contained in the cosmetics are invisible to the human eye because their size is several times smaller than the wavelength of visible light. We use this feature, for example, in transparent auto cosmetics which contain nanoparticles of silicone oxide or zircon oxide, which do not change the colour but give the surface the required hardness and resistance to scratching. They penetrate the pores and microscopic cracks in lacquer and so protect lacquer from further scratching. Other chemical components highlight the sheen and depth of lacquer.

The principle of PIKATEC CERAMIC nanocosmetics

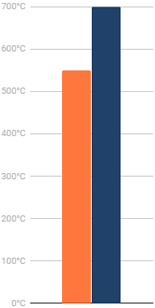

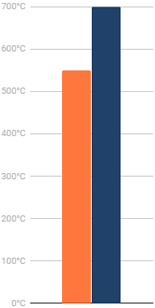

The revolutionary new series of PIKATEC CERAMIC nanocosmetics is derived from the supreme DIAMOND series; however it has been optimised to be affordable to the wider public. It provides high UV protection for lacquer and gives a hardness and resistance to abrasion several times better the previous cosmetic series. It is more water repellent and seals pores in lacquer for a period of up to one year. Its setting time is shorter and it is very resistant to industrial detergents. It is extremely resistant to heat – up to around 550°C.

The PIKATEC CERAMIC series is specially developed and produced from self-supporting emulsion and nanoparticles of a size of up to 30 nm (nm – nanometre – one billionth of a metre), which are permanently dissolved in the liquid environment of the new generation cosmetic emulsion thanks to a special solvent. These solid particles contain silicon oxide and zircon oxide, which together improve the repelling properties in relation to liquids as wells as resistance to mechanical surface wear and tear. Other components of the revolutionary PIKATEC CERAMIC cosmetics provide a protective shield against other impurities, chemicals and salts, but most of all they provide a perfect UV filter against UV radiation.

Ceramic Nano Shampoo – impurity remover, shampoo (150 ml)

A new formula of nano-preparation that highlights lacquer. In the first phase it is used to clean and remove impurities before Ceramic Nano Armour (nano-polish for car bodywork) is applied. In the second phase it is used to maintain the surface of the bodywork after Ceramic Nano Armour has been applied and to prolong the service life of this polish. After the polish has been applied try to avoid the use of industrial detergents on the car if possible. (They often destroy all protective polishes and surfaces, including wax.) However, the new formula has also significantly improved the resistance to these detergents. A treated surface of the bodywork exposed to washing (15 times) with a very strong detergent solution has lost only 10 % of its hydrophobic properties. (Test with detergent: 50 ml of detergent in 2 litres of water – each time washing an identical spot on the bodywork for one minute).

Nanoparticles (billionths of a metre) easily penetrate pores on the surface and remove stains caused by oil and insects. This preparation is optimised for manually washing car, ship and motorcycle bodywork. It is harmless to the environment.

Ceramic Nano Armour – polish for the bodywork (50 ml)

A nanotechnological preparation that creates an invisible transparent layer of nanoparticles (billionths of a metre). A hard protective shield is created in this way. The polish penetrates pores and microscopic cracks in lacquer and protects it from further damage. It levels the surface and reduces its aerodynamic resistance. As a result flying objects easily rebound from the layer of nanoparticles and do not create scratches and grooves. The same applies to insects that come into contact with the bodywork. The effect of the preparation lasts for a long time – 12 months. It will provide a high sheen protection from scratches caused by small pebbles and dirt, protection from the influence of salt and bitumen, protection from pollen and resin from trees, protection from bird excrement and particularly from UV radiation. The polish should be applied exclusively on surfaces pre-washed with Ceramic Nano Shampoo. The new formula is significantly resistant even to detergents. A surface exposed to washing (15 times) with a very strong detergent solution has lost only 10% of its hydrophobic properties. (Test with detergent: 50 ml of detergent in 2 litres of water – each time washing an identical spot for one minute). Ceramic Nano Armour is developed to withstand extreme temperatures of up to 550°C.

Ceramic Nano Clear Glass – impurity remover for glass (40 ml)

A preparation used to remove impurities before Ceramic Nano Protect Glass (nano protection of glass) is applied. Nanoparticles (billionths of a metre) easily enter the pores and remove the impurities settled in the structure of glass.

Ceramic Nano Protect Glass – polish for glass (40 ml)

A revolutionary new, uncompromising and ultimate formula of nanotechnological hydrophobic preparation. It serves as protection against impurities and water. It has a long-term effect of up to one year. The nanoparticles (billionths of a metre) create an invisible transparent layer on the surface of glass, a hard protective shield of a kind, which penetrates the pores of glass, smooths the surface and reduces its aerodynamic resistance. As a result flying objects lightly rebound from the surface and do not create long scratches and grooves in the glass. Protection against insects that come into contact with the bodywork functions similarly. No (or hardly any) long smudges obstructing the driver’s view are created on the glass. The hydrophobic preparation works on the principle of a lotus effect whereby droplets of water glide down along the surface thanks to gravitational pull or air flow. These drops of liquid, rolling along the surface of the glass, remove particles of dirt that have stuck to the glass. When it rains, a self-cleaning effect takes place and it is not necessary to use windscreen wipers from speeds of about 60 km/h (according to the incline of the glass). However, you should always ensure that your driving is safe!

Proto kupuji znovu.

CERAMIC or DIAMOND?

The basic building block of the two rows is a special patented resin functioning as a carrier for the emulsion nanoparticles and other chemical substances improving protection properties.

|  |

Diamond series was developed to meet the toughest criteria. Due to its composition is able to cope with extreme conditions. When looking for the best and uncompromising protection for your car, Diamond Series is just for you.

Ceramic series based on a series Diamond, its composition was adjusted to cosmetics was affordable. Even though it has excellent properties.

Comparison of properties

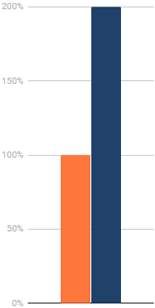

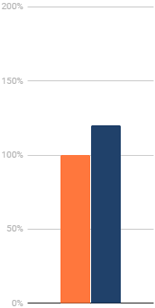

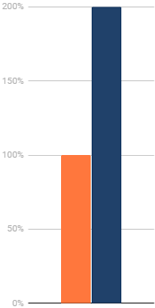

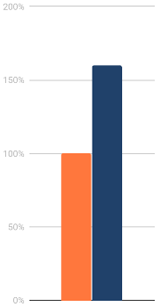

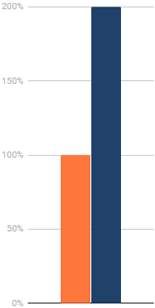

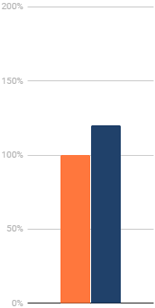

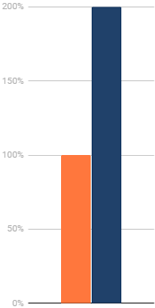

Nanoparticles of silicon and zirconium contained in the two rows are at Diamond enriched with nanoparticles of titanium and other chemicals. These increase the protective properties of tens of percent compared Ceramic series. Outside better grip and softness Diamond series captures the differences best graphical comparison.

| Ceramic | | Diamond |

|  |  |  |  |

| Hardness | Abrasion resistance | Thermal resistance | UV radiation resistance | Salt and chemical resistance |

Which line of nano cosmetics to choose?

Generally for vehicles worth up to half a million crowns recommend buying a range of Ceramic .

In the higher priced cars then certainly choose Diamond .

| ||

|  | |

Unique nanotechnological cosmetics that create an invisible transparent layer of nanoparticles (a millionth of a metre) on the car’s lacquer or glass have a width of only several nanometres. The nanoparticles contained in the cosmetics are invisible to the human eye because their size is several times smaller than the wavelength of visible light. We use this feature, for example, in transparent auto cosmetics which contain nanoparticles of silicone oxide or zircon oxide, which do not change the colour but give the surface the required hardness and resistance to scratching. They penetrate the pores and microscopic cracks in lacquer and so protect lacquer from further scratching. Other chemical components highlight the sheen and depth of lacquer.

The principle of PIKATEC CERAMIC nanocosmetics

The revolutionary new series of PIKATEC CERAMIC nanocosmetics is derived from the supreme DIAMOND series; however it has been optimised to be affordable to the wider public. It provides high UV protection for lacquer and gives a hardness and resistance to abrasion several times better the previous cosmetic series. It is more water repellent and seals pores in lacquer for a period of up to one year. Its setting time is shorter and it is very resistant to industrial detergents. It is extremely resistant to heat – up to around 550°C.

The PIKATEC CERAMIC series is specially developed and produced from self-supporting emulsion and nanoparticles of a size of up to 30 nm (nm – nanometre – one billionth of a metre), which are permanently dissolved in the liquid environment of the new generation cosmetic emulsion thanks to a special solvent. These solid particles contain silicon oxide and zircon oxide, which together improve the repelling properties in relation to liquids as wells as resistance to mechanical surface wear and tear. Other components of the revolutionary PIKATEC CERAMIC cosmetics provide a protective shield against other impurities, chemicals and salts, but most of all they provide a perfect UV filter against UV radiation.

Ceramic Nano Shampoo – impurity remover, shampoo (150 ml)

A new formula of nano-preparation that highlights lacquer. In the first phase it is used to clean and remove impurities before Ceramic Nano Armour (nano-polish for car bodywork) is applied. In the second phase it is used to maintain the surface of the bodywork after Ceramic Nano Armour has been applied and to prolong the service life of this polish. After the polish has been applied try to avoid the use of industrial detergents on the car if possible. (They often destroy all protective polishes and surfaces, including wax.) However, the new formula has also significantly improved the resistance to these detergents. A treated surface of the bodywork exposed to washing (15 times) with a very strong detergent solution has lost only 10 % of its hydrophobic properties. (Test with detergent: 50 ml of detergent in 2 litres of water – each time washing an identical spot on the bodywork for one minute).

Nanoparticles (billionths of a metre) easily penetrate pores on the surface and remove stains caused by oil and insects. This preparation is optimised for manually washing car, ship and motorcycle bodywork. It is harmless to the environment.

Ceramic Nano Armour – polish for the bodywork (50 ml)

A nanotechnological preparation that creates an invisible transparent layer of nanoparticles (billionths of a metre). A hard protective shield is created in this way. The polish penetrates pores and microscopic cracks in lacquer and protects it from further damage. It levels the surface and reduces its aerodynamic resistance. As a result flying objects easily rebound from the layer of nanoparticles and do not create scratches and grooves. The same applies to insects that come into contact with the bodywork. The effect of the preparation lasts for a long time – 12 months. It will provide a high sheen protection from scratches caused by small pebbles and dirt, protection from the influence of salt and bitumen, protection from pollen and resin from trees, protection from bird excrement and particularly from UV radiation. The polish should be applied exclusively on surfaces pre-washed with Ceramic Nano Shampoo. The new formula is significantly resistant even to detergents. A surface exposed to washing (15 times) with a very strong detergent solution has lost only 10% of its hydrophobic properties. (Test with detergent: 50 ml of detergent in 2 litres of water – each time washing an identical spot for one minute). Ceramic Nano Armour is developed to withstand extreme temperatures of up to 550°C.

Ceramic Nano Clear Glass – impurity remover for glass (40 ml)

A preparation used to remove impurities before Ceramic Nano Protect Glass (nano protection of glass) is applied. Nanoparticles (billionths of a metre) easily enter the pores and remove the impurities settled in the structure of glass.

Ceramic Nano Protect Glass – polish for glass (40 ml)

A revolutionary new, uncompromising and ultimate formula of nanotechnological hydrophobic preparation. It serves as protection against impurities and water. It has a long-term effect of up to one year. The nanoparticles (billionths of a metre) create an invisible transparent layer on the surface of glass, a hard protective shield of a kind, which penetrates the pores of glass, smooths the surface and reduces its aerodynamic resistance. As a result flying objects lightly rebound from the surface and do not create long scratches and grooves in the glass. Protection against insects that come into contact with the bodywork functions similarly. No (or hardly any) long smudges obstructing the driver’s view are created on the glass. The hydrophobic preparation works on the principle of a lotus effect whereby droplets of water glide down along the surface thanks to gravitational pull or air flow. These drops of liquid, rolling along the surface of the glass, remove particles of dirt that have stuck to the glass. When it rains, a self-cleaning effect takes place and it is not necessary to use windscreen wipers from speeds of about 60 km/h (according to the incline of the glass). However, you should always ensure that your driving is safe!

Proto kupuji znovu.

CERAMIC or DIAMOND?

The basic building block of the two rows is a special patented resin functioning as a carrier for the emulsion nanoparticles and other chemical substances improving protection properties.

|  |

Diamond series was developed to meet the toughest criteria. Due to its composition is able to cope with extreme conditions. When looking for the best and uncompromising protection for your car, Diamond Series is just for you.

Ceramic series based on a series Diamond, its composition was adjusted to cosmetics was affordable. Even though it has excellent properties.

Comparison of properties

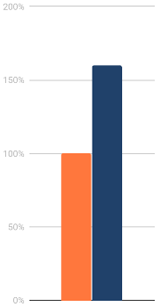

Nanoparticles of silicon and zirconium contained in the two rows are at Diamond enriched with nanoparticles of titanium and other chemicals. These increase the protective properties of tens of percent compared Ceramic series. Outside better grip and softness Diamond series captures the differences best graphical comparison.

| Ceramic | | Diamond |

|  |  |  |  |

| Hardness | Abrasion resistance | Thermal resistance | UV radiation resistance | Salt and chemical resistance |

Which line of nano cosmetics to choose?

Generally for vehicles worth up to half a million crowns recommend buying a range of Ceramic .

In the higher priced cars then certainly choose Diamond .

| ||

|  | |

ContactAnetu

ContactAnetu

Gift idea

Gift idea