The outer windows of ships, whether they are windscreens, side windows or glass doors to the cabins of ships, are exposed to extreme influences of nature and weather. The action of water, salts, minerals, chemicals and other impurities that adhere to them disrupts the glass surface. Everything is further enhanced by intense sunlight and strong UV radiation and high temperature. These factors cause irreversible damage to the glass. We can consider those places one of the most stressed parts of the ship and at the same time one of the most important, especially when it comes to passenger protection and safety. A safe view is a priority on the ship, but damaged and "blurred" glass significantly impairs transparency and a safe view. This is due to limescale, salt and common chemicals and greases, which act on the glass and etch its structure very quickly. Glass damaged in this way can no longer be cleaned, it gets further more dirty, the damage grows and the glass starts to whiten. Wherever the action of water combines with the sunshine, the process of glass damage is further accelerated.

The outer windows of ships, whether they are windscreens, side windows or glass doors to the cabins of ships, are exposed to extreme influences of nature and weather. The action of water, salts, minerals, chemicals and other impurities that adhere to them disrupts the glass surface. Everything is further enhanced by intense sunlight and strong UV radiation and high temperature. These factors cause irreversible damage to the glass. We can consider those places one of the most stressed parts of the ship and at the same time one of the most important, especially when it comes to passenger protection and safety. A safe view is a priority on the ship, but damaged and "blurred" glass significantly impairs transparency and a safe view. This is due to limescale, salt and common chemicals and greases, which act on the glass and etch its structure very quickly. Glass damaged in this way can no longer be cleaned, it gets further more dirty, the damage grows and the glass starts to whiten. Wherever the action of water combines with the sunshine, the process of glass damage is further accelerated.

The Nano Protect Glass BOAT polish smoothes the surface of glasses, polycarbonates or mirror surfaces and creates a flexible, hard layer of nanoparticles of silicon and zirconium oxides. The treatment closes the surface perfectly. Thanks to the chemical and special mixture of resin and nanoparticles on the surface, a very durable shield is created, which protects the glass surface from damage, whether it is salt, UV minerals or other chemicals. Thanks to the nano layer, the protected surface gets less dirty and its maintenance is very easy. Thanks to the extra strong water repellency, the water drops roll quickly away from the surfaces and traces of those that remain on the glass can be easily wiped off. The protective polish thus protects against limescale, salt and other chemicals that act on the surface of the glass, penetrate its structure and can hardly be removed over the time. Bacteria and microorganisms that have previously settled and multiplied on the untreated glass have nowhere to adhere to the treated surface. Based on our experience the protection layer on the glass lasts at least for one year, but it is even sufficient to apply glass protection polish once every 2 years. Do you want to learn more about the technology?

The Nano Protect Glass BOAT polish smoothes the surface of glasses, polycarbonates or mirror surfaces and creates a flexible, hard layer of nanoparticles of silicon and zirconium oxides. The treatment closes the surface perfectly. Thanks to the chemical and special mixture of resin and nanoparticles on the surface, a very durable shield is created, which protects the glass surface from damage, whether it is salt, UV minerals or other chemicals. Thanks to the nano layer, the protected surface gets less dirty and its maintenance is very easy. Thanks to the extra strong water repellency, the water drops roll quickly away from the surfaces and traces of those that remain on the glass can be easily wiped off. The protective polish thus protects against limescale, salt and other chemicals that act on the surface of the glass, penetrate its structure and can hardly be removed over the time. Bacteria and microorganisms that have previously settled and multiplied on the untreated glass have nowhere to adhere to the treated surface. Based on our experience the protection layer on the glass lasts at least for one year, but it is even sufficient to apply glass protection polish once every 2 years. Do you want to learn more about the technology?

CAUTION: The product can only be polished with the aid of the product Nano Degreaser & Polisher BOAT. Always apply to surfaces free of all impurities.

Package contents and consumption

The package contains 50 ml of Nano Protect Glass BOAT, amount sufficient for up to 10 m2. Price for protecting of 1m2 je is therefore 4,40 EUR. For surface preparation and final polishing is neessary to use Nano Degreaser & Polisher BOAT as well.

Salt vs. Fresh Water.

All products are customized for extreme and demanding environments of marine conditions (salt water). Therefore, they are absolutely sufficient for fresh water as well. The only exception is protective polishes intended for the part of the ship below the waterline. There is a difference for use in salt or fresh water and it is more described directly unfer this product, which we call Antifouling protection. The key is not to confuse Home products with Boat products. Household products are not designed for such extreme conditions and their functionality therefore could be limited. That´s why there is a price difference connected to the higher concentration of nanoparticles and active ingredients.

All products are customized for extreme and demanding environments of marine conditions (salt water). Therefore, they are absolutely sufficient for fresh water as well. The only exception is protective polishes intended for the part of the ship below the waterline. There is a difference for use in salt or fresh water and it is more described directly unfer this product, which we call Antifouling protection. The key is not to confuse Home products with Boat products. Household products are not designed for such extreme conditions and their functionality therefore could be limited. That´s why there is a price difference connected to the higher concentration of nanoparticles and active ingredients.

Applications of nanocosmetics

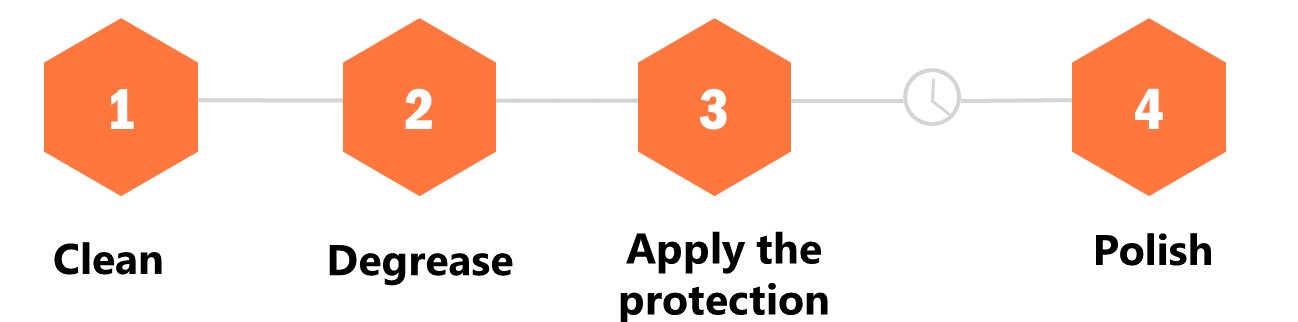

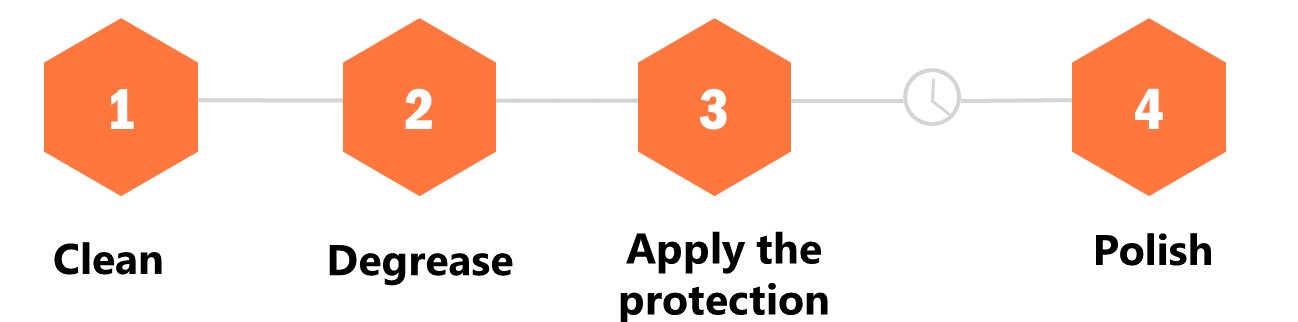

Application of the products is not complicated at all. You only need to follow the 4 steps. The surface must be thoroughly cleaned and degreased on the first place. Then apply a protective polish, leave on for 5 minutes and then polish with a Microfibre Cloth. Always read the relevant instructions in the package.

Surface Preparation

Before protection polish application clean the surface as follow: first wash the surface with PIKATEC Shampoo for boats. If salt and limescale remained on the surfaces, use Calcium Remover BOAT. The last step is to degrease the surface with product Nano Degreeser and Polisher BOAT. It must be used allways, whenever we have used a Calcium and salt remover in the step before, or we have been maintaining the surface with help of various liquid wipers in the past. If the surface was sufficiently clean and degreased though, just washing with the shampoo is enough and you can proceed straight to the application. For new boats, we recommend just degreasing the surface with the Nano Degreeser and Polisher BOAT before application. To this way prepared surface you can directly apply athe protective polish - please follow the instructions below.

Before protection polish application clean the surface as follow: first wash the surface with PIKATEC Shampoo for boats. If salt and limescale remained on the surfaces, use Calcium Remover BOAT. The last step is to degrease the surface with product Nano Degreeser and Polisher BOAT. It must be used allways, whenever we have used a Calcium and salt remover in the step before, or we have been maintaining the surface with help of various liquid wipers in the past. If the surface was sufficiently clean and degreased though, just washing with the shampoo is enough and you can proceed straight to the application. For new boats, we recommend just degreasing the surface with the Nano Degreeser and Polisher BOAT before application. To this way prepared surface you can directly apply athe protective polish - please follow the instructions below.

Surface maintenance after application

Surfaces treated with Pikatec nanocosmetics are smoother, much more resistant to damage and for their maintenance just water and Microfibre Cloth is sufficient.

With that you will be able to wipe off all dirt easily, the treated surfaces will always look like new . If the surface remains still greasy after wiping with a cloth, we recommend degreasing the greasy area once in a while with our Nano Degreeser and Polisher BOAT. The hydrophobic effect will be restored and the surface will be getting less dirty again.

With that you will be able to wipe off all dirt easily, the treated surfaces will always look like new . If the surface remains still greasy after wiping with a cloth, we recommend degreasing the greasy area once in a while with our Nano Degreeser and Polisher BOAT. The hydrophobic effect will be restored and the surface will be getting less dirty again.

Application of the protective nano-polishes

Always apply the protective polish on a properly prepared surface. Washed, degreased and dried. Check if there are no traces of water drops or other stains on surface. These need to be removed before application, otherwise you would "conserve" them in the protective layer and it would be very difficult to get rid of them afterwards.

Shake the product well before use and also frequently during application. Using a pump, spray just one dose of protective polish on the application cloth. Using circular movements apply a continuous and very thin film of the polish to the surface. When working, try not to apply the product over the already covered area, as this would increase the laboriousness and difficulty of both application and subsequent polishing. You don't have to worry - we're in a nano environment and one layer (one swipe on the surface with an application cloth) is perfectly sufficient for surface treatment. At the moment when the cloth no longer leaves a thin film of polish during application, add another drop to it and continue working. After covering the whole area, let the polish harden for 5 minutes. For polycarbonate surfaces, first test the polish on smaller parts to make sure that the surface does not become dull after application (it is necessary for the product to be polished well to find out).

Shake the product well before use and also frequently during application. Using a pump, spray just one dose of protective polish on the application cloth. Using circular movements apply a continuous and very thin film of the polish to the surface. When working, try not to apply the product over the already covered area, as this would increase the laboriousness and difficulty of both application and subsequent polishing. You don't have to worry - we're in a nano environment and one layer (one swipe on the surface with an application cloth) is perfectly sufficient for surface treatment. At the moment when the cloth no longer leaves a thin film of polish during application, add another drop to it and continue working. After covering the whole area, let the polish harden for 5 minutes. For polycarbonate surfaces, first test the polish on smaller parts to make sure that the surface does not become dull after application (it is necessary for the product to be polished well to find out).

After 5 minutes, start polishing the surface with a microfibre cloth, lightly sprayed with the Nano Degreaser & Polisher BOAT. Do not press too hard on the cloth - if you start to feel the more effort is needed than before, add little amount of the Degreaser & Polisher on the cloth and continue working. As the cloth absorbs excess polish, it is advisable to keep folding it and turning it at the time it starts to leave smudges on the polished surface. Here is the video , where you can see the application on a car.

One to two weeks after application, it is necessary to wash the glass by hand with warm salt water and after drying clean with a cloth, on which we can lightly spray again the Nano Degreaser & Polisher BOAT. This removes remaining grease which the protective polish additionally expelled from the glass (so-called emulsifiers) and which would lower the water-repellent effect until fully removed.

Additional information:

- The protective polish cannot be removed from the surface by common cleaning chemicals. If the water-repellent properties are locally reduced, for example when greasing the surface, or by covering the nanolayer with soap residues, etc., the glass must be thoroughly washed with warm water and, if necessary, the affected area degreased. The water-repellent effect is then renewed again.

- The protective polish is not suitable for sandblasted and otherwise surface-treated glass.

- The nanolayer does not prevent water condensation on the glass.

- Use the polish immediately after opening the bottle.

Types of hazards: Flammable liquids with possible eye damage, skin irritation, respiration hazard and specific target body organs toxicity.

The outer windows of ships, whether they are windscreens, side windows or glass doors to the cabins of ships, are exposed to extreme influences of nature and weather. The action of water, salts, minerals, chemicals and other impurities that adhere to them disrupts the glass surface. Everything is further enhanced by intense sunlight and strong UV radiation and high temperature. These factors cause irreversible damage to the glass. We can consider those places one of the most stressed parts of the ship and at the same time one of the most important, especially when it comes to passenger protection and safety. A safe view is a priority on the ship, but damaged and "blurred" glass significantly impairs transparency and a safe view. This is due to limescale, salt and common chemicals and greases, which act on the glass and etch its structure very quickly. Glass damaged in this way can no longer be cleaned, it gets further more dirty, the damage grows and the glass starts to whiten. Wherever the action of water combines with the sunshine, the process of glass damage is further accelerated.

The outer windows of ships, whether they are windscreens, side windows or glass doors to the cabins of ships, are exposed to extreme influences of nature and weather. The action of water, salts, minerals, chemicals and other impurities that adhere to them disrupts the glass surface. Everything is further enhanced by intense sunlight and strong UV radiation and high temperature. These factors cause irreversible damage to the glass. We can consider those places one of the most stressed parts of the ship and at the same time one of the most important, especially when it comes to passenger protection and safety. A safe view is a priority on the ship, but damaged and "blurred" glass significantly impairs transparency and a safe view. This is due to limescale, salt and common chemicals and greases, which act on the glass and etch its structure very quickly. Glass damaged in this way can no longer be cleaned, it gets further more dirty, the damage grows and the glass starts to whiten. Wherever the action of water combines with the sunshine, the process of glass damage is further accelerated.

The Nano Protect Glass BOAT polish smoothes the surface of glasses, polycarbonates or mirror surfaces and creates a flexible, hard layer of nanoparticles of silicon and zirconium oxides. The treatment closes the surface perfectly. Thanks to the chemical and special mixture of resin and nanoparticles on the surface, a very durable shield is created, which protects the glass surface from damage, whether it is salt, UV minerals or other chemicals. Thanks to the nano layer, the protected surface gets less dirty and its maintenance is very easy. Thanks to the extra strong water repellency, the water drops roll quickly away from the surfaces and traces of those that remain on the glass can be easily wiped off. The protective polish thus protects against limescale, salt and other chemicals that act on the surface of the glass, penetrate its structure and can hardly be removed over the time. Bacteria and microorganisms that have previously settled and multiplied on the untreated glass have nowhere to adhere to the treated surface. Based on our experience the protection layer on the glass lasts at least for one year, but it is even sufficient to apply glass protection polish once every 2 years. Do you want to learn more about the technology?

The Nano Protect Glass BOAT polish smoothes the surface of glasses, polycarbonates or mirror surfaces and creates a flexible, hard layer of nanoparticles of silicon and zirconium oxides. The treatment closes the surface perfectly. Thanks to the chemical and special mixture of resin and nanoparticles on the surface, a very durable shield is created, which protects the glass surface from damage, whether it is salt, UV minerals or other chemicals. Thanks to the nano layer, the protected surface gets less dirty and its maintenance is very easy. Thanks to the extra strong water repellency, the water drops roll quickly away from the surfaces and traces of those that remain on the glass can be easily wiped off. The protective polish thus protects against limescale, salt and other chemicals that act on the surface of the glass, penetrate its structure and can hardly be removed over the time. Bacteria and microorganisms that have previously settled and multiplied on the untreated glass have nowhere to adhere to the treated surface. Based on our experience the protection layer on the glass lasts at least for one year, but it is even sufficient to apply glass protection polish once every 2 years. Do you want to learn more about the technology?

CAUTION: The product can only be polished with the aid of the product Nano Degreaser & Polisher BOAT. Always apply to surfaces free of all impurities.

Package contents and consumption

The package contains 50 ml of Nano Protect Glass BOAT, amount sufficient for up to 10 m2. Price for protecting of 1m2 je is therefore 4,40 EUR. For surface preparation and final polishing is neessary to use Nano Degreaser & Polisher BOAT as well.

Salt vs. Fresh Water.

All products are customized for extreme and demanding environments of marine conditions (salt water). Therefore, they are absolutely sufficient for fresh water as well. The only exception is protective polishes intended for the part of the ship below the waterline. There is a difference for use in salt or fresh water and it is more described directly unfer this product, which we call Antifouling protection. The key is not to confuse Home products with Boat products. Household products are not designed for such extreme conditions and their functionality therefore could be limited. That´s why there is a price difference connected to the higher concentration of nanoparticles and active ingredients.

All products are customized for extreme and demanding environments of marine conditions (salt water). Therefore, they are absolutely sufficient for fresh water as well. The only exception is protective polishes intended for the part of the ship below the waterline. There is a difference for use in salt or fresh water and it is more described directly unfer this product, which we call Antifouling protection. The key is not to confuse Home products with Boat products. Household products are not designed for such extreme conditions and their functionality therefore could be limited. That´s why there is a price difference connected to the higher concentration of nanoparticles and active ingredients.

Applications of nanocosmetics

Application of the products is not complicated at all. You only need to follow the 4 steps. The surface must be thoroughly cleaned and degreased on the first place. Then apply a protective polish, leave on for 5 minutes and then polish with a Microfibre Cloth. Always read the relevant instructions in the package.

Surface Preparation

Before protection polish application clean the surface as follow: first wash the surface with PIKATEC Shampoo for boats. If salt and limescale remained on the surfaces, use Calcium Remover BOAT. The last step is to degrease the surface with product Nano Degreeser and Polisher BOAT. It must be used allways, whenever we have used a Calcium and salt remover in the step before, or we have been maintaining the surface with help of various liquid wipers in the past. If the surface was sufficiently clean and degreased though, just washing with the shampoo is enough and you can proceed straight to the application. For new boats, we recommend just degreasing the surface with the Nano Degreeser and Polisher BOAT before application. To this way prepared surface you can directly apply athe protective polish - please follow the instructions below.

Before protection polish application clean the surface as follow: first wash the surface with PIKATEC Shampoo for boats. If salt and limescale remained on the surfaces, use Calcium Remover BOAT. The last step is to degrease the surface with product Nano Degreeser and Polisher BOAT. It must be used allways, whenever we have used a Calcium and salt remover in the step before, or we have been maintaining the surface with help of various liquid wipers in the past. If the surface was sufficiently clean and degreased though, just washing with the shampoo is enough and you can proceed straight to the application. For new boats, we recommend just degreasing the surface with the Nano Degreeser and Polisher BOAT before application. To this way prepared surface you can directly apply athe protective polish - please follow the instructions below.

Surface maintenance after application

Surfaces treated with Pikatec nanocosmetics are smoother, much more resistant to damage and for their maintenance just water and Microfibre Cloth is sufficient.

With that you will be able to wipe off all dirt easily, the treated surfaces will always look like new . If the surface remains still greasy after wiping with a cloth, we recommend degreasing the greasy area once in a while with our Nano Degreeser and Polisher BOAT. The hydrophobic effect will be restored and the surface will be getting less dirty again.

With that you will be able to wipe off all dirt easily, the treated surfaces will always look like new . If the surface remains still greasy after wiping with a cloth, we recommend degreasing the greasy area once in a while with our Nano Degreeser and Polisher BOAT. The hydrophobic effect will be restored and the surface will be getting less dirty again.

Application of the protective nano-polishes

Always apply the protective polish on a properly prepared surface. Washed, degreased and dried. Check if there are no traces of water drops or other stains on surface. These need to be removed before application, otherwise you would "conserve" them in the protective layer and it would be very difficult to get rid of them afterwards.

Shake the product well before use and also frequently during application. Using a pump, spray just one dose of protective polish on the application cloth. Using circular movements apply a continuous and very thin film of the polish to the surface. When working, try not to apply the product over the already covered area, as this would increase the laboriousness and difficulty of both application and subsequent polishing. You don't have to worry - we're in a nano environment and one layer (one swipe on the surface with an application cloth) is perfectly sufficient for surface treatment. At the moment when the cloth no longer leaves a thin film of polish during application, add another drop to it and continue working. After covering the whole area, let the polish harden for 5 minutes. For polycarbonate surfaces, first test the polish on smaller parts to make sure that the surface does not become dull after application (it is necessary for the product to be polished well to find out).

Shake the product well before use and also frequently during application. Using a pump, spray just one dose of protective polish on the application cloth. Using circular movements apply a continuous and very thin film of the polish to the surface. When working, try not to apply the product over the already covered area, as this would increase the laboriousness and difficulty of both application and subsequent polishing. You don't have to worry - we're in a nano environment and one layer (one swipe on the surface with an application cloth) is perfectly sufficient for surface treatment. At the moment when the cloth no longer leaves a thin film of polish during application, add another drop to it and continue working. After covering the whole area, let the polish harden for 5 minutes. For polycarbonate surfaces, first test the polish on smaller parts to make sure that the surface does not become dull after application (it is necessary for the product to be polished well to find out).

After 5 minutes, start polishing the surface with a microfibre cloth, lightly sprayed with the Nano Degreaser & Polisher BOAT. Do not press too hard on the cloth - if you start to feel the more effort is needed than before, add little amount of the Degreaser & Polisher on the cloth and continue working. As the cloth absorbs excess polish, it is advisable to keep folding it and turning it at the time it starts to leave smudges on the polished surface. Here is the video , where you can see the application on a car.

One to two weeks after application, it is necessary to wash the glass by hand with warm salt water and after drying clean with a cloth, on which we can lightly spray again the Nano Degreaser & Polisher BOAT. This removes remaining grease which the protective polish additionally expelled from the glass (so-called emulsifiers) and which would lower the water-repellent effect until fully removed.

Additional information:

- The protective polish cannot be removed from the surface by common cleaning chemicals. If the water-repellent properties are locally reduced, for example when greasing the surface, or by covering the nanolayer with soap residues, etc., the glass must be thoroughly washed with warm water and, if necessary, the affected area degreased. The water-repellent effect is then renewed again.

- The protective polish is not suitable for sandblasted and otherwise surface-treated glass.

- The nanolayer does not prevent water condensation on the glass.

- Use the polish immediately after opening the bottle.

Types of hazards: Flammable liquids with possible eye damage, skin irritation, respiration hazard and specific target body organs toxicity.

ContactAnetu

ContactAnetu